Continuous Improvement of our Eco-Friendly Packaging Methods

In 2010, Bestar implemented a new eco-friendly packaging method that completely eliminates the need for polystyrene. This change allows us to eliminate the need for more than 6,000 m³ of polystyrene per year. This represents over 70 truck loads (40-feet) per year! In addition, our green packaging is 100% recyclable and meets the Furniture Package Performance Testing Method Standard. This guarantees that our products are delivered in good condition.

We work closely with our suppliers, Emballages Jean Cartier and Emballages LM, for the continuous improvement of techniques and products used. Thus, we express our understanding of this customer need and demonstrate our expertise on product transportation through our distributors.

A Responsible Procurement Strategy Focused on Local Suppliers

Among its environmental considerations, Bestar promotes responsible procurement through the purchase of materials and products from local suppliers. Various partnerships with these suppliers, such as Tafisa and Panolite, also contribute to this environmental value. This strategy takes several forms, whether within the office or in the factory.

First, all panels are made with recycled wood fiber obtained from controlled sources. They meet the TSCA Title VI standards from the California Legislation on Formaldehyde Emissions.

Next, to laminate our panels, we favor the use of water-based resins, free of volatile organic additives, and the use of non-toxic, 100% solid thermofusible PVA resin for the application of our edging strip.

We also contribute to sustainable development with our biodegradable cleaning products made from recycled paper. All of our packaging is 100% recyclable.

Bestar Is Committed to Respecting the Environment

The science of sustainable development is complex, but the potential for creating positive changes is almost infinite. Bestar recognizes that the desire to preserve and renew our planet’s resources is a driving force for the company. Our approach is measurable. Our commitment is long term. Overall, we are on a steady path toward a smaller environmental footprint!

By using 100% recyclable packaging products, by optimizing the management of production waste, and by recycling water vapors from our central heating system, we are placing environmental considerations at the heart of Bestar’s priorities.

Residual Materials Management

Each year, Bestar improves its residual materials and plant waste management processes. Our company implements projects that aim to reduce the amount of material sent to the landfill.

For several years, Bestar has been selling its cardboard, clear plastic, iron and wood chip rejects, as well as nonconforming particle pieces to recycling companies that process these materials in order to create new products.

To reduce our environmental impact, we ensure the recovery and proper treatment of our batteries, fluorescent lights, waste oil, used solvents, and washing water.

About half of our factory waste (dry material other than sawdust, which is fully reused) is used for thermal recovery.

Since 2010, recycling bins have been placed in the factory so that the staff can deposit all recyclable materials in the proper containers. In addition, with the help of the city of Lac-Mégantic, the company has set up a composting program.

Reduction of Electricity Consumption

Bestar employees take care to limit their electricity consumption, in particular by systematically shutting down the equipment and the dust collection system during breaks.

Other energy consumption reduction initiatives include control of our consumption by an employee who has direct access to the company’s usage log at Hydro-Québec, adjustment of the lighting according to space and time of operation, and replacement of the old lighting systems by energy-efficient and environmentally friendly ones.

Other initiatives, such as the installation of automatic equipment shutdown systems when not in use, prevent overuse of the equipment and reduce maintenance requirements.

By leveraging energy conservation, which is beneficial both economically and environmentally, Bestar contributes to sustainable development.

Reduction of Water Consumption

In recent years, at the employees’ request, Bestar has considerably reduced its water consumption by recycling the steam condensate produced by the central heating system. This employee-driven initiative allows us to reduce our consumption of chemical additives, which are also necessary for the proper functioning of the system, by allowing us to recover them.

More recently, we also changed our toilet tanks, which lets us save water.

The events of 2013 have raised awareness about the preservation of the environment, once again demonstrating its fragility. The economy and the reuse of water take on a new meaning and are perceived as very important to us.

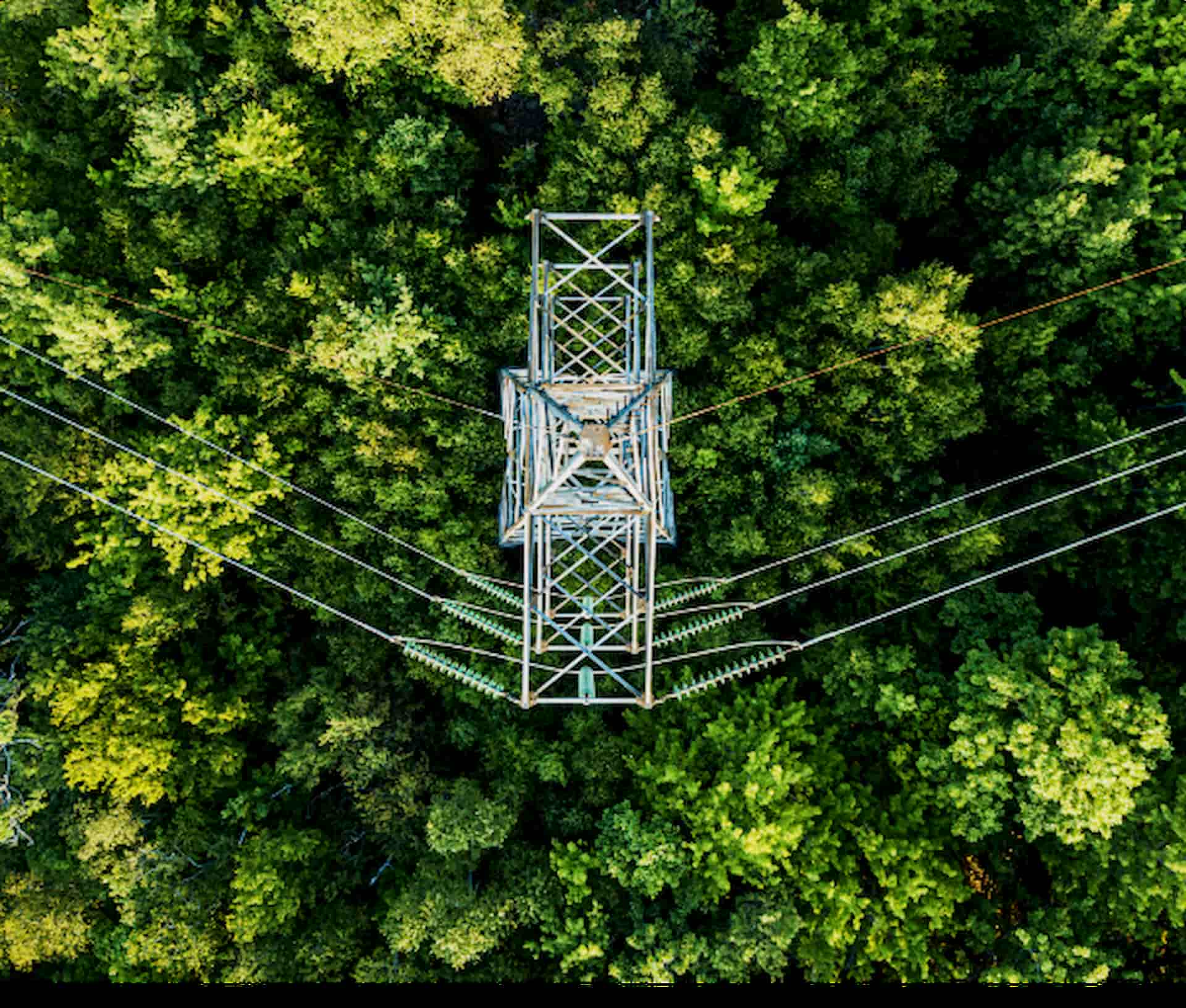

Bestar Contributes to Tree Planting

Bestar is committed to making a healthier, more sustainable planet for future generations. That is why we plant one tree for every purchase made on our website.

Thanks to your support, we regularly donate to the Arbor Day Foundation to help with the restoration of forests and areas affected by natural disasters. Trees are a natural means of counteracting carbon pollution, and we respect and understand the importance of reforestation and afforestation. Together, we contribute to a greener and cleaner environment.